The standard modules of automation

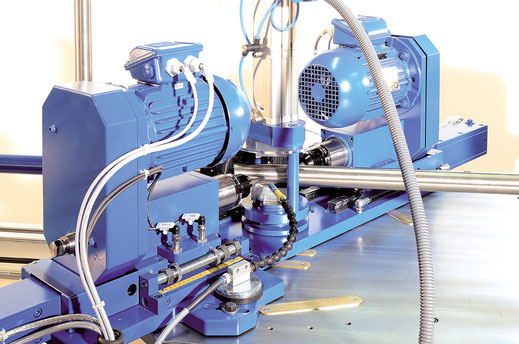

During the last decades our machines were developed from specified individual solutions to an intelligent modular construction system. On basis of RBV a modular system of processing components was created, that can be combined according to process demands.

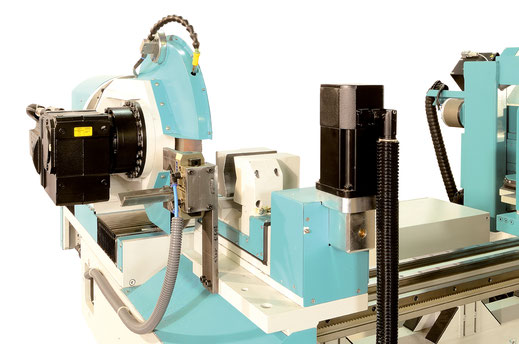

The basic modules of our RBV range

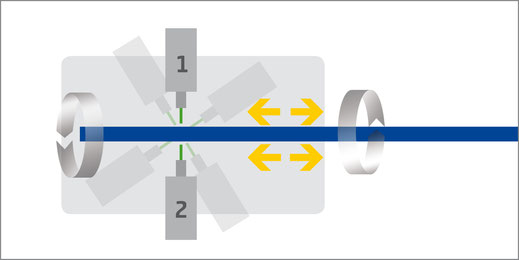

For the horizontal processing of rods and profiles

The RBV basic module contains 2 working spindles, optionally with rotating tool magazine for working processes as drilling, flow drilling and thread forming. Both spindles can be swiveled so that the drillings are also possible diagonally in profile. The work piece will be put in by hand.

By the axial and rotating feed of the work piece the position of the drilling will be defined precisely.

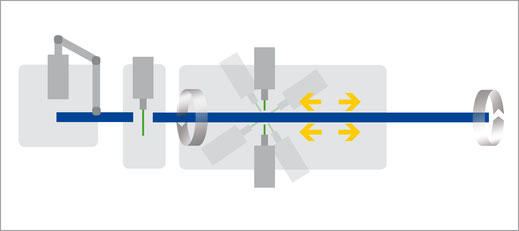

EXTENSION OF WORK PIECE FEED

A RBV version with automated work piece feed. For this version magazines for tubes / rods / profiles up to 12 m length are possible for a smooth work piece feeding to the processing centre.

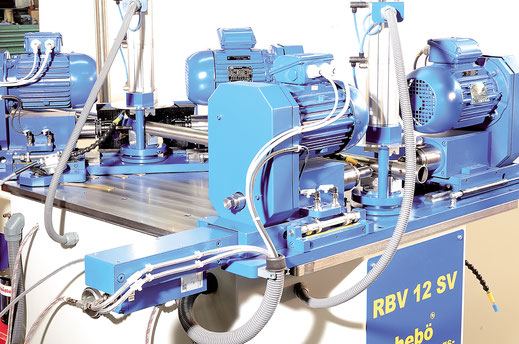

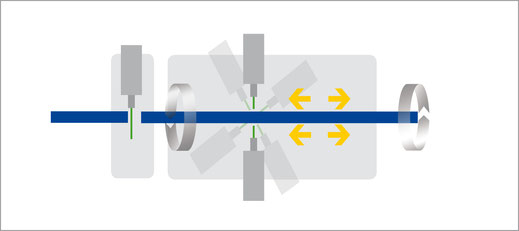

EXTENSION 4 WORKING SPINDLES

Tube and profile processing with 4 working spindles for high efficient processes.

EXTENSION SAW MODULE

RBV version with two drive spindles. After tube or profile processing of rods (up to 12 m length) the exact cutting of tube or profile will be done with a saw module.

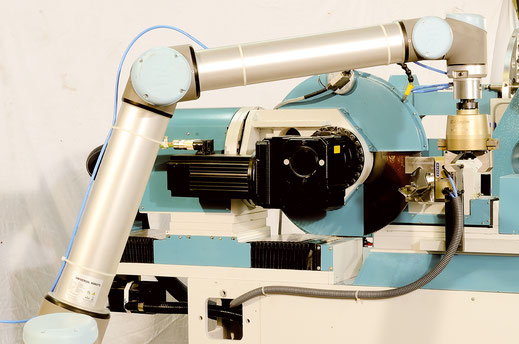

EXTENSION ROBOTIC

RBV version with saw module and a robotic arm that takes out the finished and exactly cut work pieces out of the machine and put them down e.g. into a cage pallet.

We can only show standard processes here. Further processes can developed for implementation after your individual components are produced, e.g. debarring, degreasing, washing or packaging of your work pieces. Please do not hesitate to contact us with your production demands and ideas.